Keep the Equipment and Docks Running

Concrete repair that doesn’t slow down your operation.

Bumps and hits are going to happen, even with the most careful forklift and truck operators. The damage leads to hazardous conditions that put employee safety and product quality at risk. Employees face trips and falls due to concrete surface damage. Materials fall off forklifts operating on uneven surfaces.

With Commercial Concrete Solutions, there’s a way to quickly repair concrete surfaces, so you can minimize work comp claims and unscheduled equipment maintenance due to rough surfaces. And it can be done without shutting down since our process lets you return to service in as few as 15 minutes after the repair is complete.

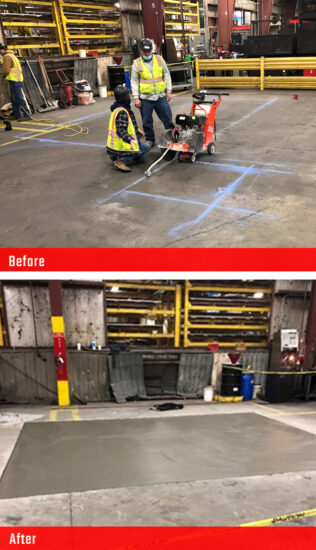

Heartland Coca Cola Distribution Center purchased a new piece of equipment and it required a new concrete slab with very detailed specifications. The repair technicians at CCS tore out and replaced the concrete using a specific mix of concrete that reached 3,000 PSI in just 1 day meeting their requirements. Normal high early concrete would take at least 3 days to reach 3,000 PSI. We accommodated the customers operating schedule by tearing out the area at night and pouring back the area the next morning. SPX had purchased a new piece of equipment which required a new concrete slab inside their facility with very detailed specifications. Repair technicians at CCS used great care to remove existing sections of concrete where the equipment was to be located. These locations were excavated and prepped with a new rock base and rebar structure as per the design. We then installed a 12″ thick concrete slab over a 12″ compacted base with a flat and level surface within a 1/4″ over the entire area to ensure a flat surface for equipment mounts. All processes were performed while SPX was operating at full capacity with little impact on their daily activities. Dust levels were kept at a minimum to ensure a safe work environment for SPX as well as CCS employees. This project was completed in just 2 days. National Beef had a 1,400 SF production area concrete floor that was pitted and had several trenches worn into it causing damage to the wheels of their industrial carts – which cost several thousand dollars to replace! Tearing out and replacing the concrete would have cost the company thousands in downtime. We worked around the clock and completed the entire job in 32 hours. We were able to go in and fill all of the pitted areas and trenches. Then we applied a chemical resistant coating. The client was so pleased they had us do the same process on another area right away. Sulfuric acid is a dangerous chemical capable of corroding skin, paper, metal, and yes, even concrete. Exide Technologies’ flooring had become this colorless, oily, liquid chemical’s victim, causing cracks and spalls along the indoor tour route. The solution was to repair the damage with an acid-resistant product. Easy enough, but downtime isn’t an option for Exide Technologies, a lead-acid battery manufacturer that supplies automotive and industrial industries. Rather than interrupting their manufacturing, the CCS team performed the repair during the plant’s scheduled shut down at the holidays. What wasn’t easy was Exide Technologies’ environmental conditions – acidic with temperatures approaching the 100-degree Fahrenheit mark. Project Time – 1 week In a battle between forklift and bollard at Piston Automotive, the forklift won. In fact, it knocked over the bollard. CCS was called in for a concrete foundation repair that would be strong enough to hold the bollard upright again and regain structural integrity. Nothing can slow down manufacturing and warehouse industry, and it’s difficult to repair forklift-related damage to concrete. CCS performed the repair in just 30 minutes, and it was ready for forklift traffic in just 15 minutes. The bollard is solid, ready to take on the next bump. “I have been in the maintenance industry for 25 years, and could never find a product that I could repair concrete from forklift damage, then I found the Pro Choice concrete patch, which works better than anything I have ever tried, and is fast drying, which is a must in the manufacturing industry. I will never use anything else again, thank you.” Tom Wenzel, Piston Automotive Project Time – 30 minutes

Heartland Coca Cola Distribution Center

SPX

National Beef

Exide Technologies

Piston Automotive